A new chapter

It happened. On December 10th, somewhere on the eastern outskirts of the Royal Capital City of Kraków, I was greeted by the following sight:

Type R ready for pickup. For various reasons the whole thing dragged on a bit; what was supposed to be 3 weeks turned into 5, but honestly, it doesn’t bother me one bit. I really like how Mariusz worked on the car. We were constantly in touch, he answered all my questions, and every now and then I’d drop by to see the progress. And every single time it was the same: I’d say I was just stopping by for 10 minutes to see how things were going, and an hour later: “Alright, I’m heading out now, because I could honestly talk cars with you all day long”. Mariusz is clearly a true enthusiast - petrol runs through his veins - and, most importantly, he approaches everything with a craftsman’s precision and dedication.

The progress of the work (in a nutshell):

First cuts and welds. Interestingly, there’s no need to remove the engine, but to avoid any cracks the windshield was cut out:

Openings for the steering column and brake booster are swapped with those of the heater unit. The best approach is to cut out surrounding rectangle from the donor’s firewall and weld it in place:

A trained eye will also notice the metal brackets for the steering column, ECU, and footrest on the LHD side. I think I’ll only ever see this area one more time, but more on that in another episode, plans have already been made.

Next, the sound deadening mat from the donor went in, everything nicely aligned:

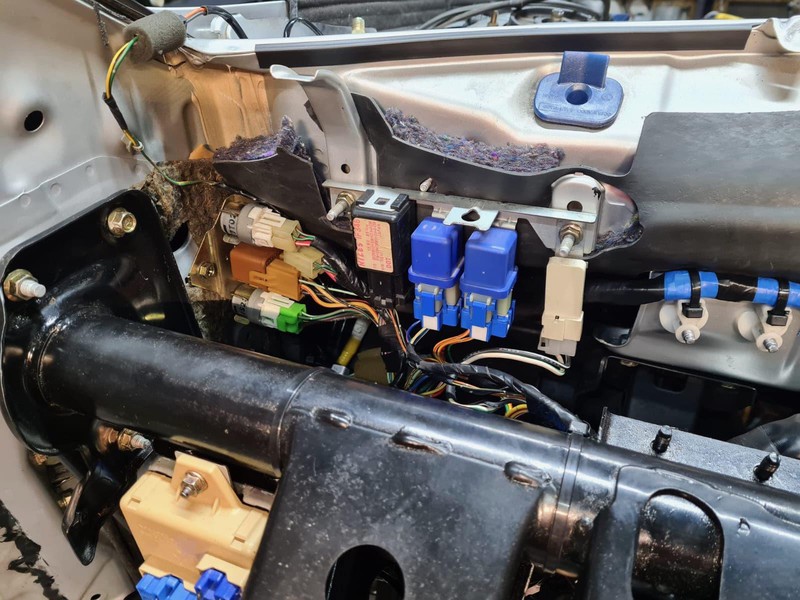

The wiring harness was taken out of the loom, there was some fun involved there. The car had some crazy hi-fi system before, which left behind a ton of extra wiring, plus an alarm and central locking (both non-functional). Everything was neatly removed.

Air conditioning turned out to be problematic. Despite trying really hard, we ended up going with manual A/C; I’ll leave “climatronic” for later. Maybe one day this thread will provide all the answers we need to get it done. So, the manual A/C wiring had to be integrated into the main loom, there’s also a new A/C condenser. Along the way, relays, a switch, and wiring for the rear fog light were added, just like in the European versions.

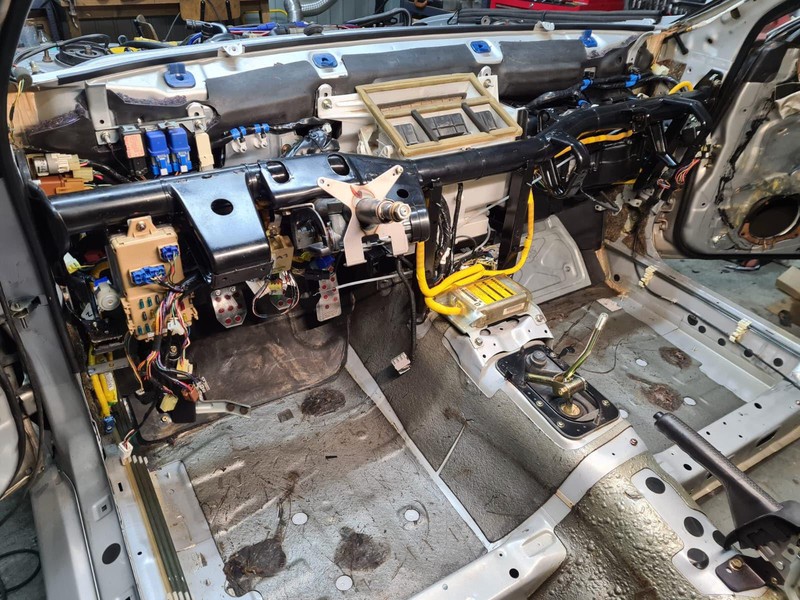

Now we’re really picking up the pace: wiper motor, brake booster, clutch master cylinder, the entire HVAC system all in place:

Once the intercooler is in, it basically means everything in the engine bay is done.

The windshield also went back into its place.

We all know Subaru is basically Lego, but the fact that a wagon carpet fits the Type R perfectly surprised me quite a lot. It’s a bit ratty, but for now it’ll have to stay that way.

Final touches:

To all those concerned: I’d like to inform you that the gaping black abyss where the passenger glovebox should be will soon be closed. The glovebox is sailing in from Japan.

The irony of this whole endeavour is that it’s December, and despite how long I waited for this car, this whole adventure started in had September 2024, and I won the auction on June 26, now the car hops straight into the garage and I have to wait again, this time until spring (yes, I know, first-world problems). I’ve driven less than 300 km so far (Kraków–Limanowa–Kraków and a trip toward Silesia), always choosing back roads, and one thing is certain: this car and I are going to get along very, very well.

In September I drove a BMW 3 Series (G20) and I remember that when I got back home and took the STI (Hawk) for a spin, I thought to myself: “Thank God there are still such mechanical inventions”. Sure, it’s a different league and comparing apples to oranges, but one thing is certain: I know which car I’d rather get into in the morning. And interestingly, I had a very similar feeling comparing the Type R to the Hawk: “Thank God there are still such crazy inventions!”

I did an MOT, well, first I got a failure (as part of the exemption process needed for non 17 characters VIN), but then the car was properly checked. The right control arm ball joint needs to be replaced - full set already ordered, maybe I’ll do it between Christmas and New Year. And the brakes. I didn’t feel super confident in the car, obviously I still need to really learn it: no ABS, very short gearbox, quick steering rack, different power steering, old tires. But during the inspection, the rear brakes didn’t stop the rollers. The plan is to try three things: bleed the system, inspect the caliper pistons, or see what’s going on with the brake bias valve; I’ll need to read up on how to adjust it.

Another observation: the clutch is a bit funny - it seems to bite right at the top, but as if only halfway, and only fully engages right at the very bottom. I’ll need to keep an eye on that.

Throttle response is also something I need to learn; in the Hawk, a rev-matched downshift requires just a blip on the gas, literally a tap and the revs are there. Here it definitely takes longer. I don’t know if that’s the map, the cable vs electronic throttle, or something else. For what it’s worth the gas cable was a bit problematic, the original didn’t really fit, neither did the donor car’s one, so we ended up fabricating a custom mounting bracket for it on the manifold.

But all that will come later. For now, the car is washed (yes, with a jack at the car wash 🙂) and tucked under a blanket.